what is pyvisa write termination character set to

If I've lured yous into the realm of SCPI automation using pyvisa to get the most from your test equipment, sooner or later, you're probably going to stop upwards in a situation where something doesn't piece of work and y'all don't know why. Or perhaps, you're in a situation where something does work but you don't know why. Debugging SCPI automation tin be a little difficult, but there are a few things you can do to brand your life easier.

Hello Instrument? Are you there?

A common trap for beginners is to fail at the first step – establishing communications with your instrument. Debugging these issues can be rather straightforward, but requires a methodical approach. When you find that yous can't see your musical instrument attempting to exercise a list_resources() telephone call, or yous're not getting a response/failing on a timeout on an *IDN?, there are a few things to check.

I like to start at the musical instrument commencement – check that it is SCPI-programmable and navigate its settings menu to ensure that the desired interface type is selected and properly configured. This is different for every instrument, merely most instruments usually only allow one type of interface to be active at any time even if there are several. Some instruments also allow your interface to exist changed between modes – eastward.g. USB-CDC which emulates a COM port, or USB-TMC which behaves equally a USB488 Examination and Measurement Class device.

For USB, if yous have the option, using USB-TMC is probably the meliorate one where y'all intend to use it with a VISA layer equally it can emulate GPIB status lines, while USB-CDC is easier to work with for those wanting to write programs using a serial library but can also be used with a VISA layer with some limitations.

For Ethernet, make sure that you have set the advisable addressing fashion for your network – DHCP will machine-configure an address from a DHCP server, which can change over time. Static IP addressing sets a fixed accost, although you lot should make sure y'all choose an address which does non disharmonize with any other node on the network.

In one case this is checked, and so you should cheque if the physical link is operational. For USB, this tin be done by watching Device Manager (nether Windows) or the issue from lsusb or dmesg (under Linux). Under Windows, your device should announced in a separate USB Test and Measurement Devices section and exist displayed every bit an USB Exam and Measurement Device (IVI).

![]() For USB-TMC devices, there is no need to install whatever drivers or build any drivers equally the IVI Foundation drivers bundled within the NI-VISA installer should pick up the hardware. Exercise not utilise the NI Commuter Wizard for USB-TMC devices as you may gamble causing driver conflicts!

For USB-TMC devices, there is no need to install whatever drivers or build any drivers equally the IVI Foundation drivers bundled within the NI-VISA installer should pick up the hardware. Exercise not utilise the NI Commuter Wizard for USB-TMC devices as you may gamble causing driver conflicts!

If yous find that your device is detected as an Unknown Device, or has a yellow exclamation marking, then you may have either a hardware compatibility issue or a driver problem. Endeavour changing USB cables, USB ports and computers to see if this changes anything. Avoid using hubs, especially depression-cost ones, every bit they tin can cause bug or be sensitive to external electromagnetic interference. Try updating your USB controller drivers – it could also be that your equipment may non similar particular USB controllers. Finally, I have encountered problems where this was due to multiple conflicting VISA installations on a single reckoner – in this case, uninstalling NI-VISA, rebooting and re-installing the latest version of NI-VISA usually fixes this.

Under Linux, y'all should run across a new device underlsusb. If you lot do not, consult your dmesg for further hints every bit to whether the device was detected or whether an fault occurred during enumeration. Similar troubleshooting steps are recommended in case this is the issue. As the drivers used for pyvisa-py are user-state, kernel back up for USB-TMC is non necessary – simply ensure yous accept pyusb installed.

For Ethernet, this can exist seen in the link lights on your switch or instrument and can be verified past checking the instrument has received an IP address. You can usually also visit the IP address in a web browser to ostend that it is on the network – if this succeeds, you're gear up to move on.

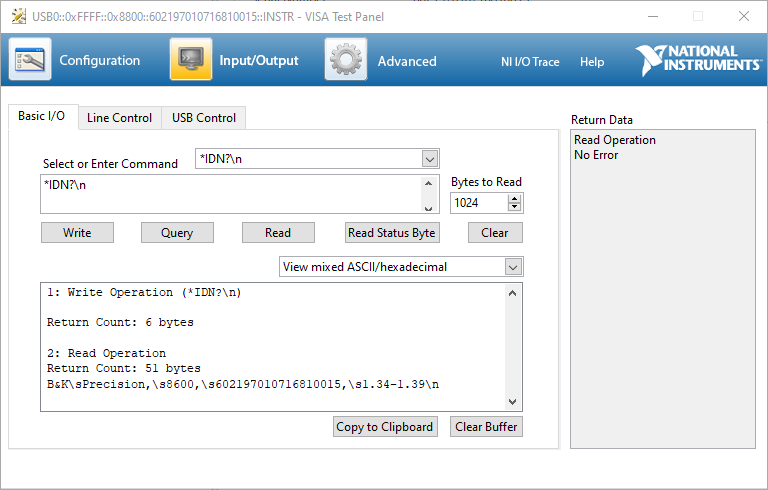

At present that the hardware is detected, yous should be able to talk to your device – on Windows using NI-VISA, this is easily checked by invoking NI MAX to check your devices:

Clicking on the device and the VISA Examination Panel, so selecting Input/Output allows you to transport and receive commands interactively to cheque the communication.

I'm non aware of a direct equivalent for Linux, all the same, information technology should exist possible just to motion on straight to Python and list devices from in that location using:

import pyvisa rm = pyvisa.ResourceManager() rm.list_resources()

If you do not receive whatever output under Linux, ensure that y'all have pyvisa-py and pyusb installed and effort invoking Python equally the root user every bit your user account may not have sufficient privileges to access USB devices.

From in that location, you should be able to verify musical instrument performance with a short program that reads the instrument'south identity and prints it out:

import pyvisa rm = pyvisa.ResourceManager() instrument = resource_manager.open_resource("RESOURCESTRING") print(instrument.query("*IDN?") Unremarkably, for instruments over USB/VXI-11/HiSLIP, this volition only work. For instruments connected over TCP/IP sockets and Series connections and for some fussy instruments, you will demand to configure the termination characters.

For TCP/IP sockets, usually adding instrument.read_termination="\n" will be sufficient, every bit that tells VISA when to finish reading – otherwise it sits waiting for more information until it times out after (by default, after two seconds).

Some instruments may need to take both read_termination and query_termination ready, while others may demand read_termination and write_termination ready, so information technology is often a instance of experimentation (or checking the transmission) to notice out which settings are right for your instrument. While '\n' (newline) is the most common termination, there may be some instruments that want '\r' (railroad vehicle render) instead or a combination '\r\n'.

Once you have reached this stage, you're definitely set up to write more complex programs, merely that usually will get y'all into some deeper trouble relatively quickly.

Tracing the Execution

Assuming you now have a pyvisa program, things will inevitably go incorrect at some signal and for some reason, your script may fail with an exception or the instrument may beep indicating a SCPI Mistake occurred, but what really happened? Very oftentimes, it's hard to find out, especially if the program has been running for hours if not days before an fault cropped up.

To get to the bottom of this in a way that is cross-platform may simply be to modify your programme such that you can trace its execution. This may involve replacing any write and queryfunctions with your own office that not only executes the function simplylogs the part that is executed. To do this, the Python logging module can exist used which will provide conveniences such equally a nice date/time stamp and being able to straight the output to STDERR and a log file, and the power to suppress printing past setting the logging level.

Having a trace of the commands sent and query results from the instrument is definitely helpful, but sometimes, this can be misleading. This is in part due to the nature of SCPI commands – writes require no response so until you hit a query, y'all really don't know whether the instrument has striking an error or failed on a command. As a effect, it is also good practise (although perhaps overkill in ordinary scenarios) to check the error queue with a SYST:ERR? query after every single control and query. This will render a ii-element array with an error number and an error string describing the fault. The clarification is non always all that helpful, only more mod devices tend to be a bit more descriptive with regards to errors sometimes even including the offending control.

Negative error codes are standardised by SCPI while positive mistake codes are dependent on the vendor. Every bit a issue, referencing the manual for your musical instrument and/or the returned error text string would be nearly accurate.

Examples for equipment I own are shown below –

Keysight E36103A PSU

-440,"Query UNTERMINATED afterward indefinite response" -430,"Query DEADLOCKED" -420,"Query UNTERMINATED" -410,"Query INTERRUPTED" -400,"Query error" -363,"Input buffer overrun" -350,"Queue overflow" -330,"Cocky-examination failed" -310,"System fault" -277,"Macro redefinition not allowed" -276,"Macro recursion error" -273,"Illegal macro label" -272,"Macro execution error" -270,"Macro error" -241,"Hardware missing" -230,"Data corrupt or stale" -225,"Out of retentivity" -224,"Illegal parameter value" -223,"As well much data" -222,"Data out of range" -221,"Settings conflict" -213,"Init ignored" -211,"Trigger ignored" -200,"Execution fault" -183,"Invalid inside macro definition" -181,"Invalid outside macro definition" -178,"Expression data not allowed" -171,"Invalid expression" -170,"Expression fault" -168,"Block information not allowed" -161,"Invalid block data" -158,"String data not allowed" -151,"Invalid string data" -150,"String data error" -148,"Character data not allowed" -141,"Invalid grapheme information" -138,"Suffix not allowed" -134,"Suffix too long" -131,"Invalid suffix" -128,"Numeric information not allowed" -124,"Too many digits" -123,"Exponent likewise large" -121,"Invalid character in number" -114,"Header suffix out of range" -113,"Undefined header" -112,"Program mnemonic too long" -109,"Missing parameter" -108,"Parameter not allowed" -105,"GET non allowed" -104,"Information blazon error" -103,"Invalid separator" -102,"Syntax fault" -101,"Invalid character" -100,"Command error" 514,"LAN config mistake" 561,"Analog board - failed to salve to EEPROM" 564,"Analog lath - failed to load from EEPROM" 565,"Analog board - over temperature" 566,"Analog board - command timed out" 601,"Front panel does non respond" 609,"Organisation ADC test failed" 610,"I/O board non plugged in" 611,"Unsupported I/O board" 612,"Analog board does non respond" 613,"Analog bias output ±15V test failed" 614,"EEPROM examination failed" 615,"EEPROM salvage failed" 616,"Model no mismatched" 630,"Fan test failed" 631,"System DAC test failed" 701,"Cal security disabled past jumper" 702,"Invalid country. Cal secured" 703,"Invalid secure code" 704,"Secure code too long" 708,"Cal output disabled" 717,"Cal OVP or OCP status enabled" 721,"Failed to calibrate voltage DAC" 722,"Failed to calibrate voltage ADC" 723,"Failed to calibrate OVP" 724,"Failed to calibrate current DAC" 725,"Failed to calibrate electric current ADC" 726,"Failed to calibrate OCP" 727,"Invalid Calibration sequence" 728,"Calibration failed"

Keithley Model 2110 DMM

-101 Invalid character -102 Syntax mistake -103 Invalid separator -104 Data type fault -105 GET not allowed -108 Parameter not allowed -109 Missing parameter -112 Plan mnemonic too long -113 Undefined header -121 Invalid character in number -123 Numeric overflow -124 Also many digits -131 Invalid suffix -138 Suffix not allowed -148 Graphic symbol non allowed -151 Invalid cord information -158 String data not allowed -160~-168 Block data errors -170~-178 Expression errors -211 Trigger ignored -213 Init Ignored -214 Trigger deadlock -221 Settings conflict -222 Data out of range -223 Besides much data 223 2d role mismatch -224 Illegal parameter value 225 Role/range mismatch -230 Data Dried -350 Too many errors -410 Query INTERRUPTED -420 Query UNTERMINATED -430 Query DEADLOCKED -440 Query UNTERMINATED subsequently indefinite response 521 Input buffer overflow 522 Output buffer overflow 531 Bereft retentivity 532 Cannot achieve requested resolution 540 Cannot utilise overload as math reference 550 Command not immune in local 601 Forepart panel does not respond 602 RAM read/write failed 603 Forepart-Stop MCU does not reply 604 A/D noisy test failed 605 N2 calibration parameter failed 606 N3 calibration parameter failed 607 Buffer1 offset out of range 608 Buffer2 start out of range 609 DC proceeds x1 failed 610 DC gain x10 failed 611 DC proceeds x100 failed 612 Ohms 500 nA source failed 613 Ohms 5 uA source failed 614 DC 1000V null failed 615 Ohms x uA source failed 616 DC current sense failed 617 Ohms 100 uA source failed 618 DC high voltage attenuator failed 619 Ohms 1 mA source failed 620 Air-conditioning rms zero failed 621 AC rms full scale failed 624 Unable to sense line frequency 640 Meas setting failed 641 Meas reading failed 642 Board Protect failed 650 Panel failed 651 Panel Program Checksum Error

Rohde & Schwarz HMC8043/HMP4040 PSU

0, "No mistake" -100, "Command error" -102, "Syntax error" -221, "Settings disharmonize" -350, "Queue overflow"

B&K Precision Model 8600 DC Electronic Load

101 DESIGN Error: Too many numeric suffices in Control Spec 110 No Input Command to parse 114 Numeric suffix is invalid value 120 Parameter of type Numeric Value overflowed its storage 130 Wrong units for parameter 140 Wrong blazon of parameter(south) 150 Wrong number of parameters 160 Unmatched quotation mark (unmarried/double) in parameters 165 Unmatched bracket 170 Command keywords were not recognized 190 Too many dimensions in entry to exist returned in parameters 191 Besides many char -200 Execution error [generic] -221 Settings disharmonize [check current device land] -222 Data out of range [eastward.g., as well big for this device] -223 Likewise much information [out of memory; cake, string, or expression besides long] -224 Illegal parameter value [device-specific] -225 Out of memory -270 Macro error -272 Macro execution fault -273 Illegal macro label -276 Macro recursion fault -277 Macro redefinition not allowed -310 Organization mistake [generic] -350 Too many errors [errors beyond 9 lost due to queue overflow] -400 Query error [generic] -410 Query INTERRUPTED [query followed by DAB or Get before response consummate] -420 Query UNTERMINATED [addressed to talk, incomplete programming message received] -430 Query DEADLOCKED [too many queries in command string] -440 Query UNTERMINATED [after indefinite response] 0 No error i Module Initialization Lost 2 Mainframe Initialization Lost 3 Module Calibration Lost four Not-volatile RAM State section checksum failed 5 Non-volatile RAM RST section checksum failed 10 RAM selftest eleven CVDAC selftest 1 12 CVDAC selftest 2 13 CCDAC selftest 1 fourteen CCDAC selftest two fifteen CRDAC selftest 1 16 CRDAC selftest 2 20 Input Downwardly 40 Flash write failed 41 Wink erase failed 80 Digital I/O selftest error 213 RS-232 buffer overrun error 216 RS-232 receiver framing mistake 217 RS-232 receiver parity fault 218 RS-232 receiver overrun error 220 Forepart panel UART overrun 221 Front console UART framing 222 Front panel UART parity 223 Front panel buffer overrun 224 Front panel timeout 225 Front CRC check error 226 Front cmd Error 401 CAL switch prevents calibration 402 CAL password is incorrect 403 CAL not enabled 404 Computed readback cal constants are incorrect 405 Computed programming cal constants are incorrect 406 Incorrect sequence of calibration commands 407 CV or CC status is incorrect for this command 603 FETCH of information that was not acquired 604 Measurement overrange

If having eliminated near all other causes, never discount the possibility that a transient connectivity mistake, memory corruption or a bug in instrument firmware can cause bug that are hard to replicate. Sometimes these issues need to be "worked around", so writing some recovery code that showtime retries a command and declining that, closes the instrument, attempts to re-open and reconfigure it may be a better option. Other instruments may demand to be ability cycled to regain command, so investing in some remote-controlled Ac sockets could exist handy. In any case, you will demand to take worked with your instrument for a while to understand its quirks and idiosyncrasies.

Bringing the Arms

While the above method is definitely exhaustive and cantankerous-platform, sometimes you want quick answers without modifying your program. If your program works on a serial connection, perchance you could use a protocol sniffer. If your musical instrument connects via Ethernet, a packet sniffer could also work. Just those tools are more generalised tools which aren't necessarily tailored to debugging SCPI programs.

Enter the NI I/O Trace tool which NI-VISA users can use to diagnose programs that interact with NI-VISA and the IVI drivers.

This is akin to a network sniffing tool, just that it sniffs calls to NI-VISA and IVI drivers. It seems to be a flake dated at first glance and has a very simple user interface, but is extremely powerful. By default, the configuration is a footling limiting, so perhaps it's good to brand some changes.

The kickoff alter may be but to increment the phone call history depth to something bigger – this manner if your program interacts with the instrument very oftentimes, you can have a meaningful amount of data displayed on the screen. The logging tab is probably the almost of import change – enabling Log to File is vitally of import equally this will let a running log of calls even when it exceeds the telephone call history depth. This way, you tin re-load this file afterward you end the capture and go through more than history than what is shown on the screen. Keeping the file blazon as a Trace File gives you the maximum flexibility, only text and XML are too bachelor.

The View Selection allows you to disable various APIs which y'all are not interested in. Furthermore, it also allows you lot to add extra columns also – if you have multiple VISA programs running at the aforementioned time, having the ProcessID and ThreadID columns may help you lot separate the calls made by each program. The Error Action tab tin can also help by taking automated actions in case of an error. Usually you're interested in when an error occurs, and so perhaps you might desire to pause or terminate the capture – merely you don't accept to do this peculiarly if y'all're logging to file. Errors are usually denoted in ruby, so you lot won't miss them.

Once yous are fix-up, you can click the green pointer button to enable capturing, run your program and picket the screen fill up with VISA calls. Unfortunately, non-printable characters seem to exist replaced past '.' characters, so don't be surprised if things look a fiddling strange, only the logged parameters also unremarkably include a byte count to indicate how much information was sent or received. Hopefully, this volition give you some idea about what's happening with your program.

Case Traces – Keithley Kickstart

The best part of using NI I/O Trace is the possibility to examine what is happening through VISA at any given fourth dimension – this includes running software provided past the vendor. This means you lot can learn about how the vendor's software performs certain operations, which tin exist quite illuminating especially if the vendor's software is a trivial limited simply does most of what you lot want, and you're looking to write something that better suits your needs.

Out of convenience, I decided to examine Keithley Kickstart 2 while information technology conducts an I-V Characterizer run. Of annotation is that this is non SCPI, as information technology uses TSP linguistic communication instead, just the concept is quite similar.

The format of an NI I/O trace can be seen above – the software sets parameters on the SMU before the run and checks for errors after every command. The command I have highlighted uses the smu.source.sweeplinear command to set up the sweep.

While the sweep is running, the software seems to hammer the SMU with checks for errors, whether the trigger model is running (i.east. whether it is still sweeping) and the buffer status in terms of number of points logged.

The software creates a plot "on the wing" as the scan is running – how does that happen? Well, it seems that every so often, when the buffer number changes, information technology retrieves the buffer values in a series of format.information and printbuffer commands. Pretty cool! Equally someone who is more used to SCPI rather than TSP, this was quite illuminating.

Conclusion

Getting SCPI automation working right tin be a scrap challenging, but with a methodical approach and some care with coding in some logging and mistake queue checks, it is possible to brand tracing out errors a flake easier.

Only if you don't want to go to all that trouble, using NI I/O Trace can be an "piece of cake way out", provided you tweak a few of the parameters to ensure you are logging to file so you don't miss all of the action. This acts almost like a packet sniffer but for VISA/IVI calls, allowing you lot to identify errors and walk through them to detect what led upward to the fault.

The tool is rather rudimentary, just every bit a benefit, it works on all software that makes calls through NI-VISA or IVI drivers including vendor software. This makes information technology possible to examine and learn from the often "limited" offset-up software that is provided so you can build something that is more suited for your needs without having to practice everything "from the ground upwards" past reading programming manuals. It tin as well help yous identify differences in programming approaches – a comparative approach can oftentimes help you identify why something works or doesn't work!

Source: https://goughlui.com/2021/07/04/tips-debugging-scpi-visa-automation-including-ni-i-o-trace/

0 Response to "what is pyvisa write termination character set to"

Post a Comment